Products ▼

ERP Solutions

Portfolio

Development

Custom Mobile, web, ERP apps, and software testing.

Media & Visual Effects

VFX, post-production, restoration, and animation services.

Creative & Branding Solutions

Innovative marketing, design, VR, and gaming services.

Cloud & IT & ITES solutions

Secure data, DevOps, cloud, and ITES solutions.

Customer Relationship Management

Effortlessly manage and enhance your customer interactions.

Human Resource Management

Streamline workforce operations and boost organizational efficiency.

Hospital Management System

Simplify and optimize all your healthcare management processes.

Project Management System

Easily track, manage, and complete tasks and projects on time.

- Home

- About Us

-

Services ▼

Development

Custom Mobile, web, ERP apps, and software testing.

Media & Visual EffectsVFX, post-production, restoration, and animation services.

Creative & Branding SolutionsInnovative marketing, design, VR, and gaming services.

Cloud & IT & ITES solutionsSecure data, DevOps, cloud, and ITES solutions.

-

Products ▼

Customer Relationship Management

Effortlessly manage and enhance your customer interactions.

Human Resource ManagementStreamline workforce operations and boost organizational efficiency.

Hospital Management SystemSimplify and optimize all your healthcare management processes.

Project Management SystemEasily track, manage, and complete tasks and projects on time.

- ERP Solutions

- Portfolio

- Career

- Blogs

- Contacts

Still Managing Production, Inventory, and Accounts Through Separate Systems?

Manufacturing businesses eventually outgrow manual tracking and disconnected systems. We implement structured ERP solutions that bring real-time control across production, inventory, and finance.

From raw materials and WIP to finished goods and GST alignment, we build phased ERP systems designed around how your factory actually operates.

ERP Solutions for Growing Manufacturing Businesses in India

Designed for Indian manufacturing SMEs that need structured operational control, production visibility, and scalable systems to support long-term growth.

Bring clarity to raw materials, work-in-progress (WIP), finished goods, finance, and production processes through a phased, business-led ERP implementation built around the operational realities of your manufacturing environment.

WHO THIS ERP IS FOR

This ERP solution is designed for manufacturing businesses that have outgrown manual systems such as Excel, Tally, WhatsApp, and disconnected tools.

Best suited for:

- Manufacturing businesses managing raw materials, work-in-progress (WIP), and finished goods

- Production-driven operations with inventory-heavy processes

- Businesses operating across one or multiple warehouse locations

- Manufacturing teams seeking structured, scalable operational systems

- Businesses ready to implement ERP with discipline and long-term adoption in mind

COMMON BUSINESS CHALLENGES WE SEE

Many growing manufacturing businesses face operational challenges such as:

- Physical stock not matching accounting or system records

- No consolidated real-time visibility across sales, purchase, production, and inventory

- Inaccurate tracking of raw materials, WIP, and finished goods

- Production planning based on manual sheets or assumptions

- Finance and GST not aligned with day-to-day operational transactions

- Dependency on a few individuals for critical data and reporting

- Delayed, inconsistent, or manually prepared management reports

- No integrated system to monitor and control core business functions

OUR ERP IMPLEMENTATION APPROACH

A Practical, Phased ERP Journey

We follow a consulting-led implementation approach designed to reduce operational disruption, control risk, and ensure long-term system adoption across production,

inventory, and finance functions.

Phase 1: Core Operational Stabilisation

- Accounting and GST configuration

- Sales and purchase process alignment

- Inventory and stock management structuring

- Production tracking with essential operational dashboards

- Foundational reporting and compliance setup

This phase focuses on stabilising core processes, improving data accuracy, and establishing system discipline before introducing advanced automation.

Phase 2: Optimisation and Process Enhancements

- Workflow refinement based on real usage

- Industry-specific configurations and modules

- Required integrations such as Tally, POS, or third-party systems

Customisation is introduced only after core operations are stable and teams are comfortable using the system.

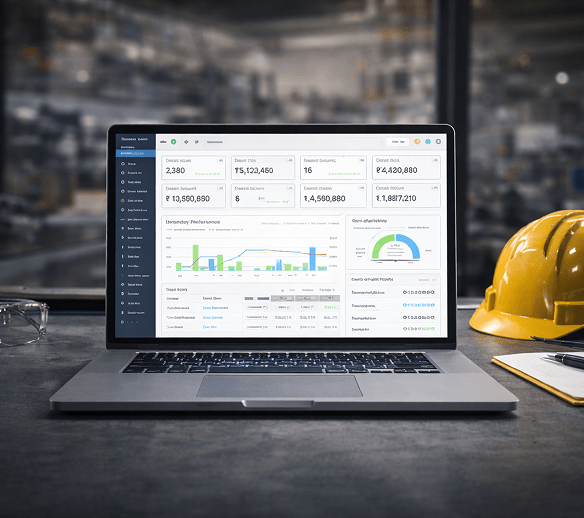

ERP PLATFORM

We implement ERP solutions using ERPNext, a flexible and license-free ERP platform widely adopted by growing manufacturing businesses in India.

Platform Strengths

- Modular and scalable architecture designed for expanding operations

- GST-ready configuration aligned with Indian compliance requirements

- Built to support manufacturing workflows, inventory control, and production tracking

- Adaptable across multi-location operations and structured process environments

OUR DOMAIN EXPERIENCE

We understand manufacturing environments where operational discipline directly impacts profitability.

Our experience includes:

- Manufacturing and supply chain process structuring

- Production planning and inventory control workflows

- ERP configuration aligned with real factory process flow

- Finance and operations alignment within a unified system

- Reporting structures designed for owner-level decision visibility

WHY AJAX MEDIA TECH

Established in 2014, Ajax Media Tech supports Indian manufacturing businesses with structured, implementation-focused ERP solutions.

What differentiates us:

- Business-first approach focused on operational control, not just software deployment

- Clear scope definition and requirement mapping before implementation begins

- Phased delivery model designed to reduce disruption and execution risk

- Emphasis on long-term system usability, process discipline, and team adoption

- Transparent timelines and structured project governance

TYPICAL OUTCOMES FROM MANUFACTURING ERP IMPLEMENTATIONS

Inventory & Finance Alignment

Outcome: Real-time stock visibility across stores and accounts

Manufacturing businesses moving from Excel and manual reconciliation to structured ERP implementation typically gain real-time visibility between physical stock and accounting records, reducing manual adjustments and reporting delays.

Production Planning Clarity

Outcome: Unified production and raw material planning

Businesses dependent on manual tracking often achieve structured production scheduling, raw material planning, and purchase coordination within one integrated system.

Reporting & Management Control

Outcome: Improved month-end reporting accuracy

With phased ERP implementation, finance and GST reporting becomes aligned with operational transactions, improving accuracy and management-level visibility.

BUSINESS OUTCOMES FROM ERP IMPLEMENTATION

After structured ERP implementation, manufacturing businesses typically achieve:

- Real-time alignment between inventory, finance, and production, reducing costly mismatches

- Clear production planning visibility across raw materials, WIP, and finished goods

- Improved GST and compliance accuracy with fewer manual adjustments

- Reduced dependency on spreadsheets and individual employees

- Structured management dashboards enabling faster operational decision- making

- Greater operational control for owners and leadership teams

Schedule a Structured ERP Discussion

Book a Free ERP Discovery Call

Schedule a structured ERP discovery call to review your manufacturing operations and system requirements.

Get in Touch

Ajax Media Tech, a top software company in Chennai, delivers world-class results with expert talent.

We`ll get back to you in 24h

044 28265326

Sintron Square, 3 & 4th Floor, I-9, Dr. V.S.I Estate, Thiruvanmiyur, Chennai – 600 041

Copyright © AJAX MEDIA TECH